WHAT IS THE PROBLEM IN THE INDUSTRY?

By nature, agricultural raw materials are loaded with numerous microbic organisms. Either before or during harvesting, processing at the factory (operators, processing floor included) or during shipment, storage. Agricultural raw materials are also potential reservoirs for cross contamination. Possible rapid development of bale bacteria but also pathogenic species like salmonella, E.coli and toxin producing fungi, can lead to huge economical impact and potential dangers for endconsumers.

WHAT ARE THE EXISTING SOLUTIONS

- Thermal treatment of products

- Different applications of biocides, fungicides on raw materials

- Application of other hazardous chemicals : acidifiers like propionic acid, formaldehyde,…

- Moisture control during processing

- AW control ( water activity of the (processed) raw material)

- Temperature control

WHY DON’T THEY SOLVE THE PROBLEM

- Some of them are too labour intensive

- Some are costly

- Some are not efficient enough

- Some are limited due to toxicity issue

- Some are hazardous

WHAT DO WE OFFER

Anolyte application

- Limited addition of anolyte depending on basic moisture content, AW level and final desired and acceptable moisture content

- Neutral pH of anolyte solution

- On site production of anolyte: maximum potential

- Application by high pressure fogging / spraying otherwise adverse effects (local high humidity zones)

- Mixing zone after application (maximum contact)

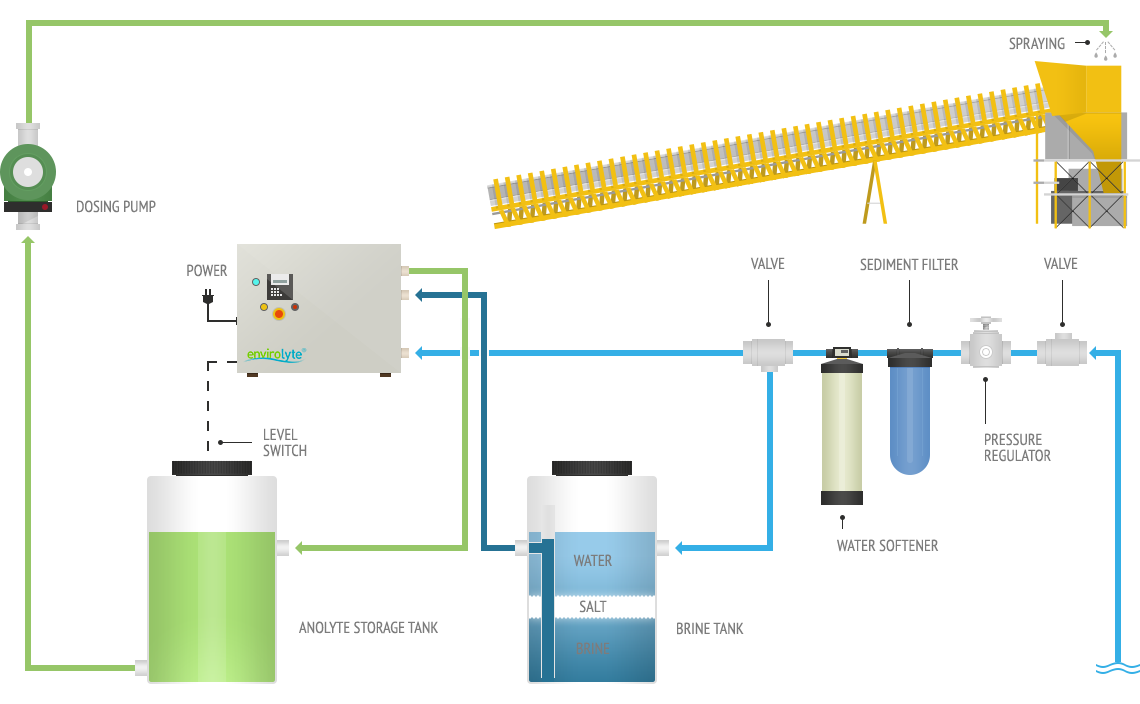

Drawing of a typical installation of Envirolyte® Feedlyte® system

Anolyte efficacy

- Up to 6 log reduction for most species including fungi, moulds

- Rapid activity

- Superior to most existing applications (acids, formaldehyde,…)

- No residues (< L.O.D.)

- No odour

- No smell

- No possible irritation

WHAT DO WE ACHIEVE

Reducing

- Microbiogical development during processing, storage, shipment. Including e.g. salmonella, enterobacteriaceae, toxin producing moulds, yeasts,…

- Self-heating risks when mid & long term storage is applied.

Enhancing

- Handling and free-flowing properties of bulkcommodities, prevents frequent raw material solidification in cells or in inner walls of bin.

Securing

- Against further contamination in the feedchain, recall, claims, financial loss.

Protecting

- Environment against toxic hazardous chemicals.

- Operators personnal health.

WHAT ARE THE BENEFITS

- Convenient

- Cheap

- Safe

- Enhanced efficacy claims

For instruction details or applications please send Your enquiry ![]()